email: hzsp@hzsuper.com

Inicio / todos / Acerca de la información del producto / What are the Different Types of Laminating Machines?

What are the Different Types of Laminating Machines?

What are the Different Types of Laminating Machines?

Lamination protects paper from tears, spills, wrinkles, and any other substance that could alter the text or graphic were it to make contact with the original paper. It also intensifies colors and improves the overall appearance of printed documents and signs. Different projects require a different weight of lamination film, depending on use and location of the item to be laminated, and finishes are available in matte, gloss, or satin.

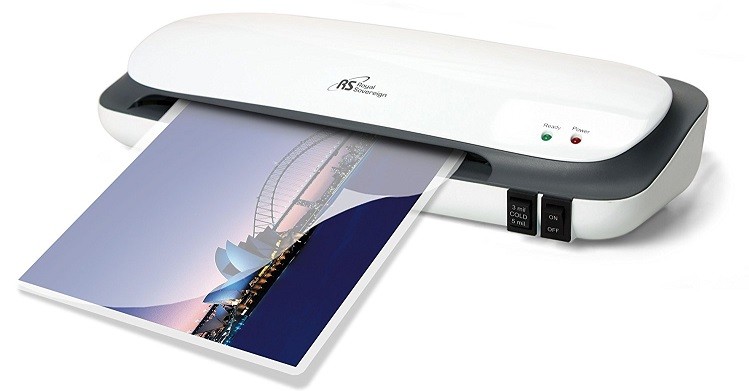

Laminating machines are either hot or cold. A hot laminating machine is the most common, but because some documents are heat sensitive, a cold machine is the most appropriate choice for some uses.

Hot Pouch Laminating Machines

For these types of laminating machines, the lamination material comes in “pouches” which are actually two sheets of plastic film bound on one edge. Items are placed in an appropriately sized pouch, trimmed, and then placed in a cardboard carrier. The carrier is a simple piece of heavy card stock, similar to a file folder, and it protects the lamination pouch from direct contact with the hot rollers. Once a machine is warmed up and your item is snugly protected in the carrier, you place the closed edge of the carrier in the mouth of the laminating machine, and the rollers pull it slowly through, heating the carrier and lamination pouch. The heat reacts with the pouch, activating an adhesive which then binds to the paper, and the carrier exits the back of the machine with the newly durable, aesthetically enhanced item, ready to be placed on a wall, in a wallet, or wherever the laminated product will find its new home.

Cold Pouch Laminating Machines

If the document was printed on an ink jet printer, came from a fax, or is a photo, it may be sensitive to heat and a hot laminating machine could cause the colors to run. Cold laminating machines use pressure to activate the special cold laminating pouches. Some don't even require electricity and operating them requires simply inserting the cold pouch and turning the crank. Safer and easier to use, cold laminating machines can be a great option, but hot machines still produce better quality and durability.

Roll Laminating Machines

Roll machines are used in commercial and industrial settings where a large poster size is desired and speed is necessary. Roll machines don't use pouches. The lamination film is on a roll that's attached to the lamination machine, and the lamination film is heated prior to contact with the paper. This increases speed and efficiency, and allows users to complete bulk laminating projects in a reasonable amount of time.

Whether you opt for hot or cold pouches, there are several other variables to consider before choosing a specific model. Pouch sizes range from ID card to poster size. Think about the projects that may spring up in the future and be sure to select a machine that can accommodate the largest pouch size you require. How heavy does your lamination need to be? Extra thick pouches are not compatible with all laminating machines as they require more intense heat than the lighter duty machines provide, so be sure to confirm the maximum pouch thickness recommended by the manufacturer. Speed should be considered as well. If you intend to use your laminating machine frequently, it would behoove you to pay a little more for a faster model.

If you want to learn more about binding machines ,please visit our website www.supubinding.com。

ADDRESS:

Jingda Road ,Shanlian Development Zone , , Hangzhou , ZheJiang

PHONE:

+86-571-88963565

E-MAIL:

hzsp@hzsuper.com

Escriba su mensaje por favor

- Móvil

- *Título

- *Contenido